Constructing a Simple and Efficient Lean-To Shed for Your Garden

This document provides a comprehensive guide to the construction of a lean-to shed, a practical and aesthetically pleasing addition to any garden. The focus is on simplicity and efficiency, prioritizing readily available materials and straightforward construction techniques. This guide assumes a basic understanding of carpentry and the use of common tools. Always prioritize safety and adhere to local building regulations.

Phase 1: Planning and Preparation

Before commencing construction, meticulous planning is crucial to ensure a successful outcome. This phase involves determining the shed's dimensions, selecting appropriate materials, and obtaining necessary permits.

1.1 Determining Dimensions and Location

The dimensions of your lean-to shed should be carefully considered based on your storage needs and available space. Consider the following factors:

- Storage Requirements: Accurately assess the volume of items you intend to store to determine the necessary internal dimensions. Allow ample space for maneuvering.

- Available Space: The shed's footprint should be carefully measured to ensure it fits comfortably against the supporting structure (e.g., house wall, fence).

- Local Regulations: Check with your local council or homeowner's association for any regulations concerning shed size, location, and materials.

Once the dimensions are finalized, mark the intended location on the ground using stakes and string. Ensure the chosen location is level and provides adequate access for construction and future use.

1.2 Selecting Materials

Choosing the right materials is vital for the longevity and stability of your lean-to shed. Consider these options:

- Pressure-Treated Timber: This is a highly durable and weather-resistant option for the frame, offering excellent protection against rot and insect infestation. Ensure it meets the appropriate treatment standards for ground contact.

- Plywood or Shiplap: These are commonly used for cladding, offering a balance of durability, cost-effectiveness, and aesthetic appeal. Choose a grade suitable for exterior use.

- Roofing Material: Options include asphalt shingles, corrugated metal sheeting, or polycarbonate panels. The choice depends on budget, aesthetic preferences, and local climate conditions.

- Fasteners: Use galvanized screws and nails to ensure corrosion resistance.

- Concrete Blocks or Posts: For the foundation, depending on the size and weight of the shed.

1.3 Obtaining Necessary Permits

Depending on your location and the size of the shed, you may need to obtain building permits. Contact your local council or planning authority to inquire about regulations and the permitting process. Failing to obtain necessary permits can result in fines or the need to dismantle the structure.

Phase 2: Foundation and Frame Construction

This phase involves creating a solid foundation and erecting the supporting frame of the lean-to shed. Proper foundation and frame construction are paramount for the stability and longevity of the structure.

2.1 Foundation Construction

The foundation provides stability and prevents the shed from sinking into the ground. For a simple lean-to, a few options exist:

- Concrete Slab: This offers the most robust and durable foundation, particularly suitable for larger sheds. Requires pouring a concrete slab of appropriate thickness and reinforcement.

- Concrete Blocks: A more cost-effective and simpler option involves laying a course of concrete blocks to create a level base. Ensure the blocks are level and stable.

- Pressure-Treated Timber Sleepers: For smaller sheds, pressure-treated timber sleepers can provide a sufficient base, ensuring proper drainage and minimizing ground contact.

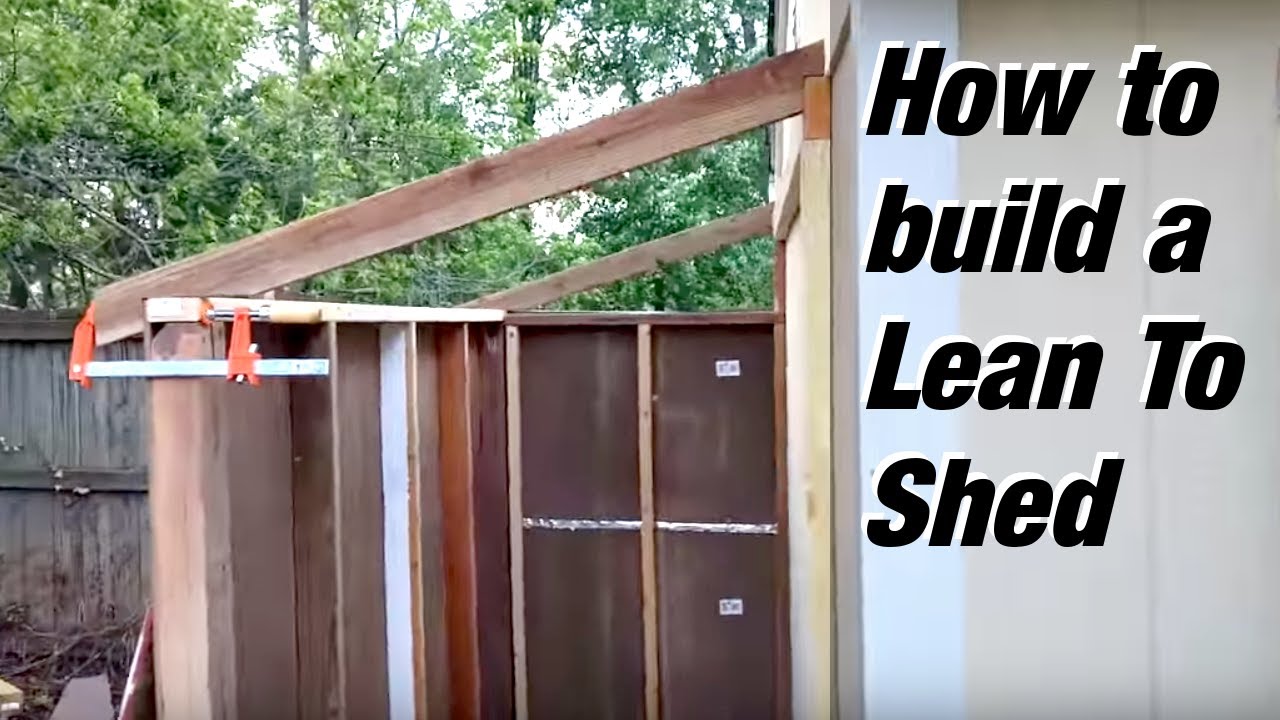

2.2 Frame Construction

The frame provides the structural integrity of the shed. The following steps outline the process:

- Construct the Base Frame: Cut and assemble the base frame using pressure-treated timber. Ensure the frame is square and level, using a spirit level to check for accuracy.

- Erect the Wall Frames: Cut and assemble the vertical wall frames, attaching them securely to the base frame. Use appropriate bracing to maintain squareness.

- Attach to Existing Structure: Securely fasten the frame to the existing structure (house wall, fence) using appropriate fasteners. Ensure a watertight seal to prevent leaks.

- Construct the Roof Frame: Cut and assemble the roof rafters, attaching them to the top of the wall frames and the supporting structure. Ensure the rafters are evenly spaced and appropriately angled for sufficient drainage.

Phase 3: Cladding and Roofing

This final phase involves covering the frame with cladding and roofing material to provide weather protection and complete the shed.

3.1 Cladding Installation

Cladding protects the shed from the elements. Follow these steps:

- Install Cladding: Begin at the bottom and work your way up, securing the chosen cladding material (plywood or shiplap) to the wall frames using screws or nails. Ensure proper overlap to prevent water ingress.

- Add Trim: Install trim around the edges of the cladding to create a neat and finished look. This also helps to protect the edges of the cladding from the elements.

3.2 Roofing Installation

The roof protects the shed's contents from rain and snow. The process depends on the chosen roofing material:

- Asphalt Shingles: Install a layer of underlayment before applying the shingles, ensuring proper overlap and alignment.

- Corrugated Metal Sheeting: Secure the sheeting to the rafters using appropriate screws and washers.

- Polycarbonate Panels: These panels are lightweight and easy to install, offering good light transmission. Secure them to the rafters using appropriate fasteners.

Phase 4: Finishing Touches

After completing the cladding and roofing, add finishing touches to enhance the shed's appearance and functionality.

4.1 Door and Window Installation

Install a door and any windows according to your design. Ensure proper weather sealing around the openings to prevent drafts and leaks.

4.2 Painting or Staining

Apply a protective coat of paint or stain to enhance the appearance of the shed and protect the timber from the elements. Choose a weather-resistant product suitable for exterior use.

Note: This guide provides a general overview of lean-to shed construction. Specific details may vary depending on the chosen materials, dimensions, and local conditions. Always refer to the manufacturer's instructions for specific materials and techniques. Consider consulting with a qualified builder or carpenter for complex projects or if you lack experience with carpentry. Remember to prioritize safety throughout the construction process, wearing appropriate personal protective equipment (PPE) and using tools correctly.

Note: Only a member of this blog may post a comment.